infsoft Calibration

The infsoft Calibration Tool supports the setup of indoor positioning based on Bluetooth Low Energy Beacons and other signal sources. It facilitates both the initial calibration of tracking environments and ongoing quality assurance during operation.

This tool is especially important when using third-party beacons for client-side positioning, as calibration is essential to ensure accurate location results. When using infsoft’s own hardware, such as Locator Beacons, calibration is not required.

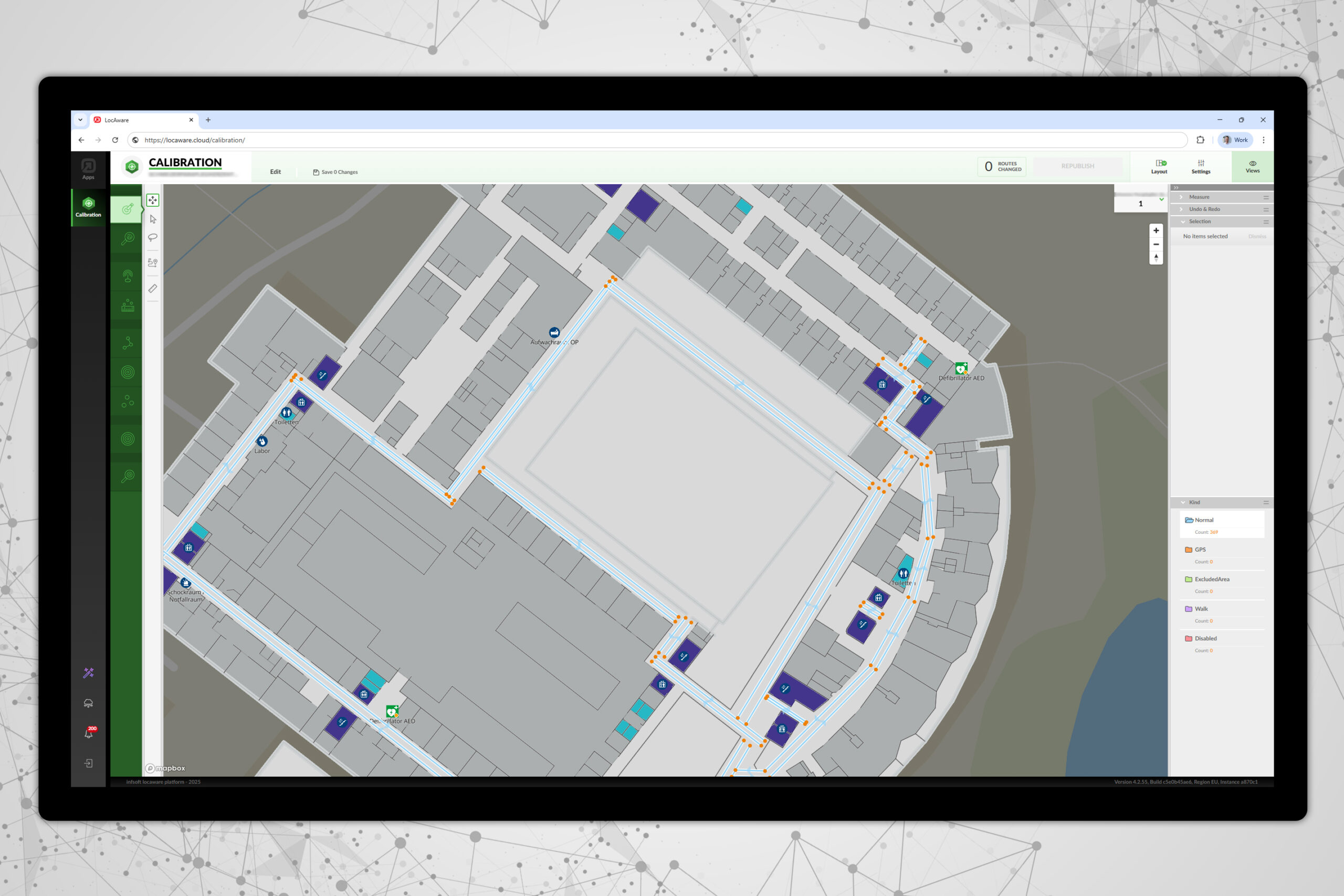

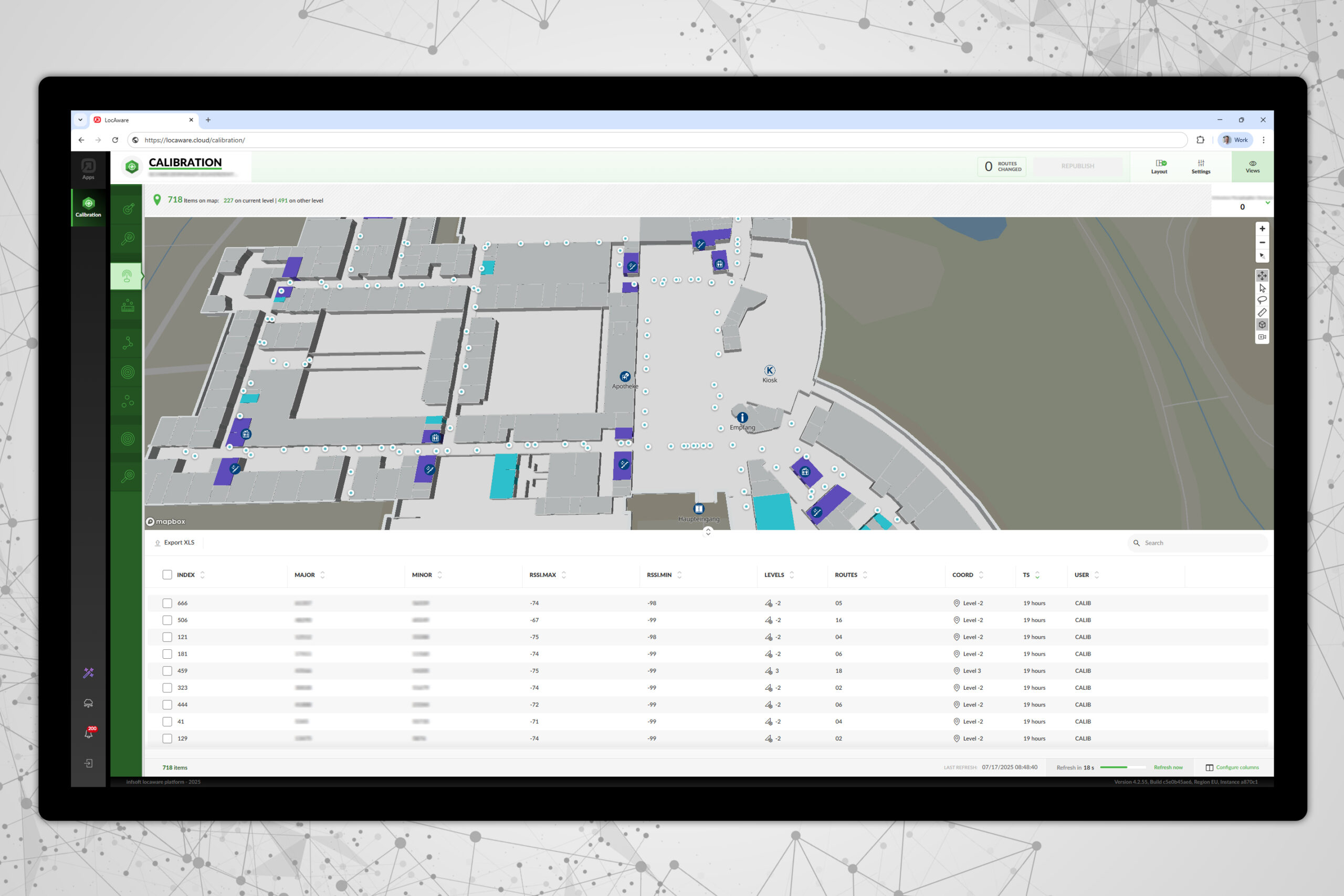

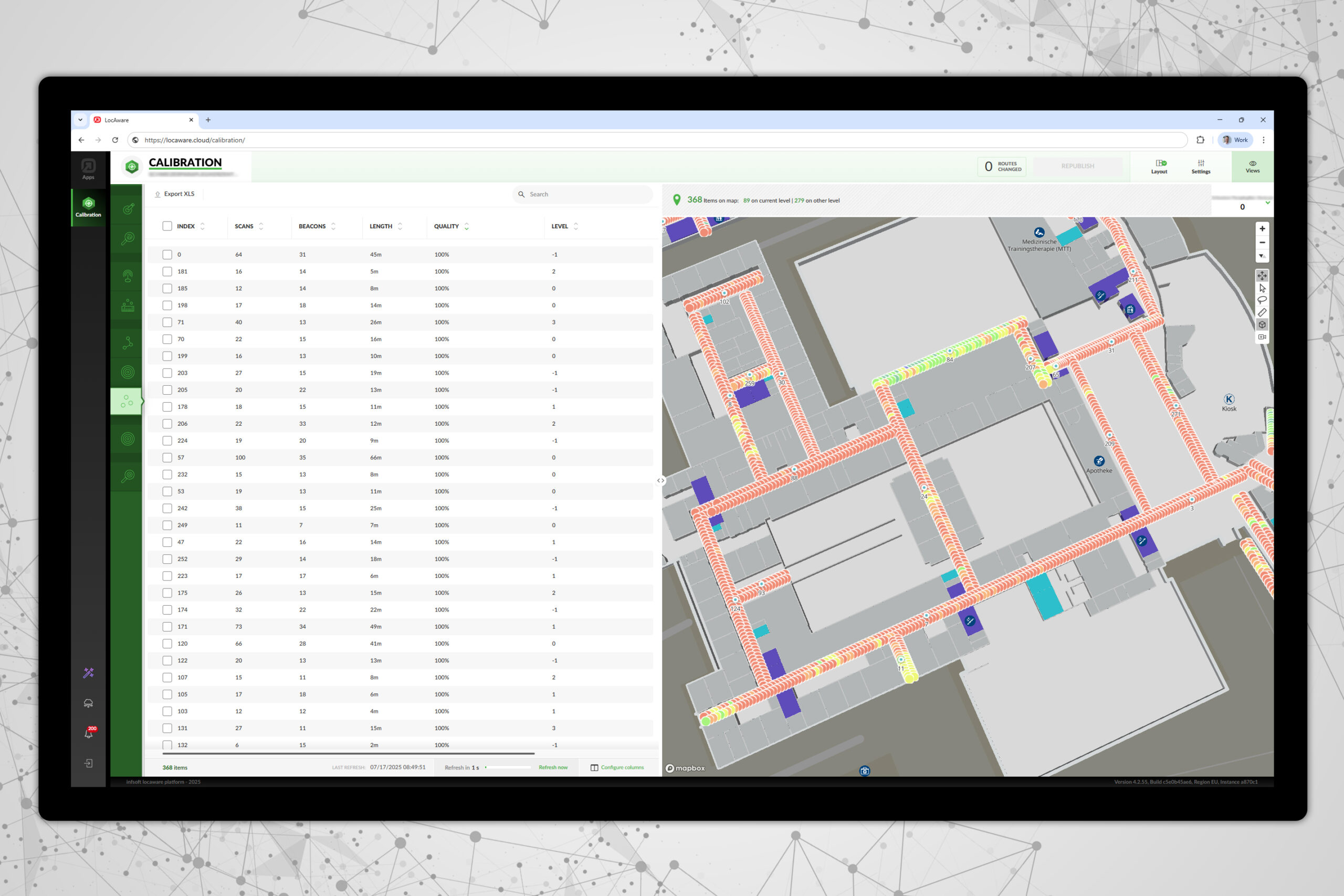

Capture and analyze calibration data

To determine precise location data, calibration routes are created in the relevant areas. The signal data collected during this process – depending on the technology used, such as Bluetooth Low Energy (BLE) – is recorded at defined intervals and exchanged between the infsoft LocAware platform® and the infsoft Calibration App.

The tool displays the planned route to the user and guides them step by step through the data collection process, ensuring complete documentation of the measurements. This data serves as the foundation for accurate position calculation within the system. Precise data capture provides the basis for consistent and reliable location determination.

Calibration with third-party beacons

Calibration is required when third-party beacons are used for location determination. By precisely measuring the beacons while considering their Proximity UUIDs and transmission parameters, these components can be fully integrated into the system – without manual hardware mapping or additional positioning.

When using infsoft Locator Beacons, this step is unnecessary, as the hardware comes pre-configured and requires no additional calibration. This ensures easy and consistent integration of different beacon types.

Quality assurance and recalibration

The Calibration Tool is used not only during initial setup but also for the regular inspection and maintenance of existing positioning environments. Changes in infrastructure – such as structural modifications, new signal sources, or hardware replacements – can be reliably addressed.

Affected areas can be recalibrated as needed to ensure consistently high positioning accuracy. This enables continuous quality management and ensures a stable, reliable, and future-proof positioning environment throughout the system’s entire lifecycle.