TDK-Micronas GmbH

Digital Transformation in Semiconductor Manufacturing at TDK-Micronas

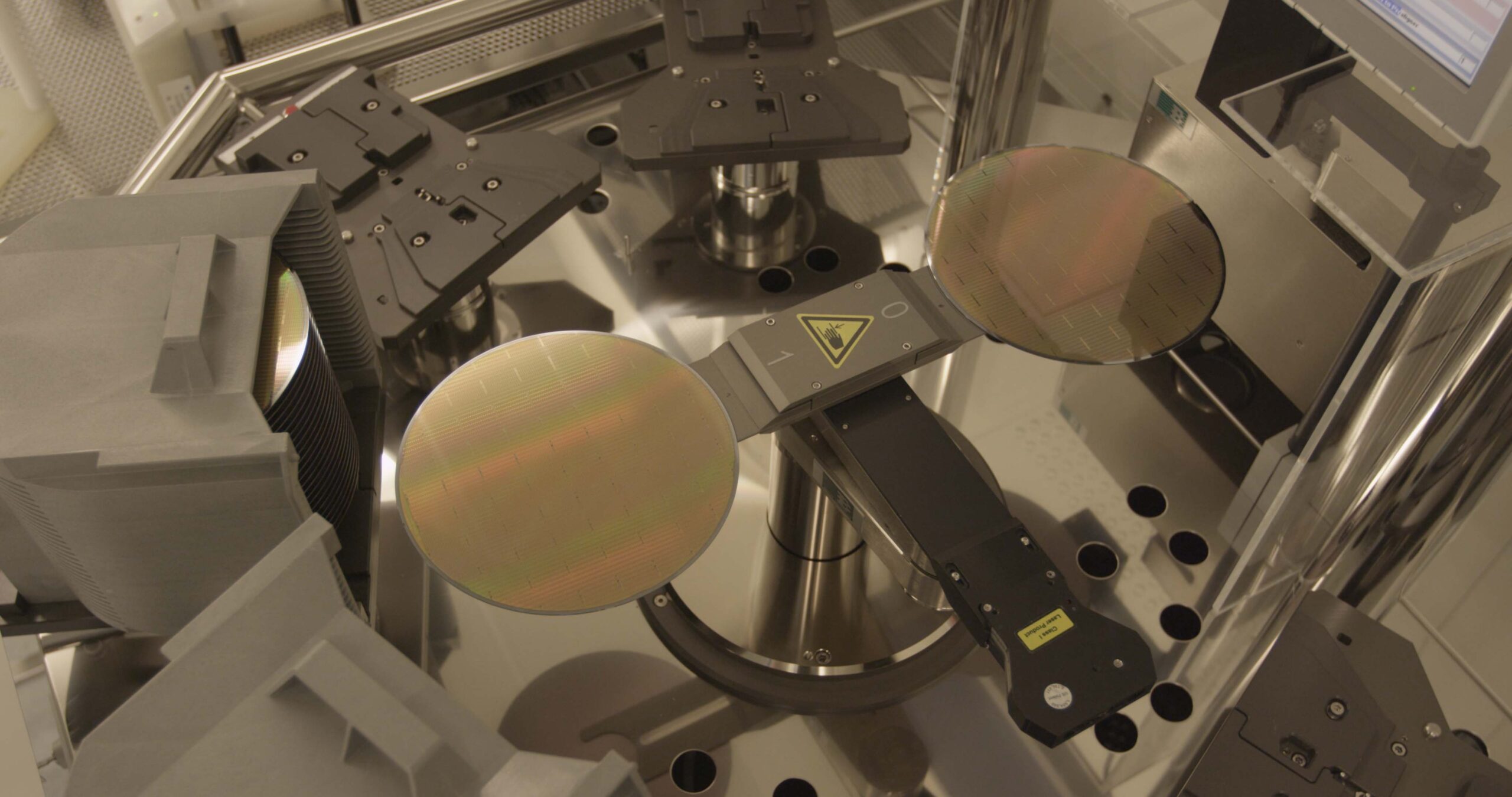

At its Freiburg site, TDK-Micronas operates a fully integrated wafer fabrication facility for magnetic field-based CMOS sensors – covering the entire process from production and assembly to final testing. Within the cleanroom environment, the company relies on digital tracking across an area of 3,600 m² to monitor approximately 1,700 wafer boxes.

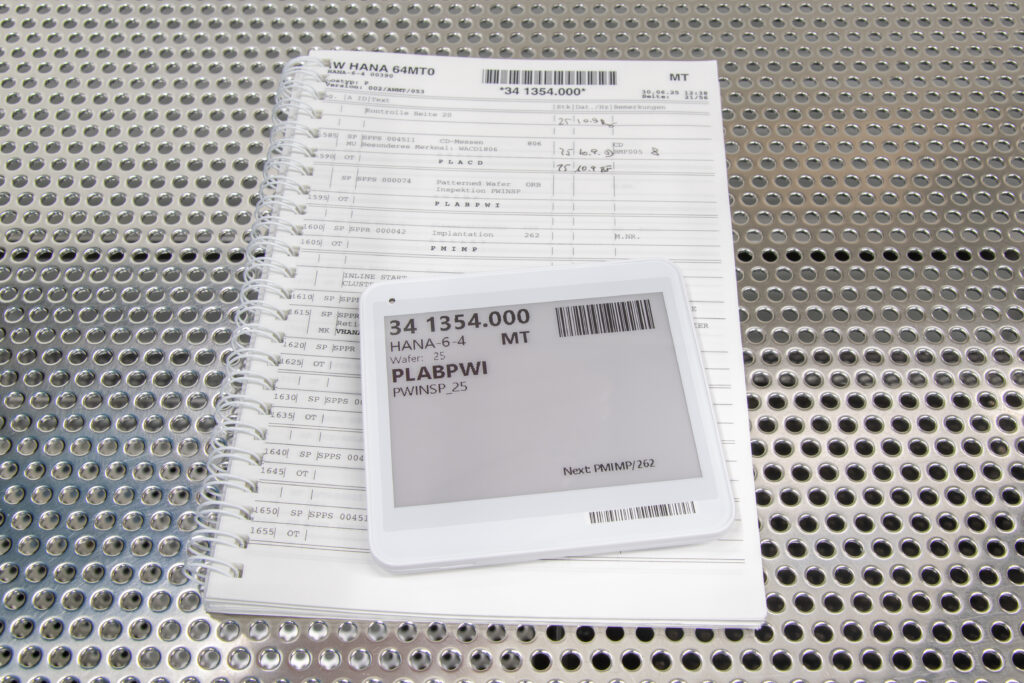

The solution enables real-time, end-to-end traceability, eliminates media disruptions, enhances process reliability, and increases both efficiency and sustainability in manufacturing. The previously paper-based workflow – requiring around 160,000 sheets of special cleanroom paper annually – has been completely replaced by electronic E-Ink displays.

The Previous Process

Paper-Based Workflows with Manual Constraints

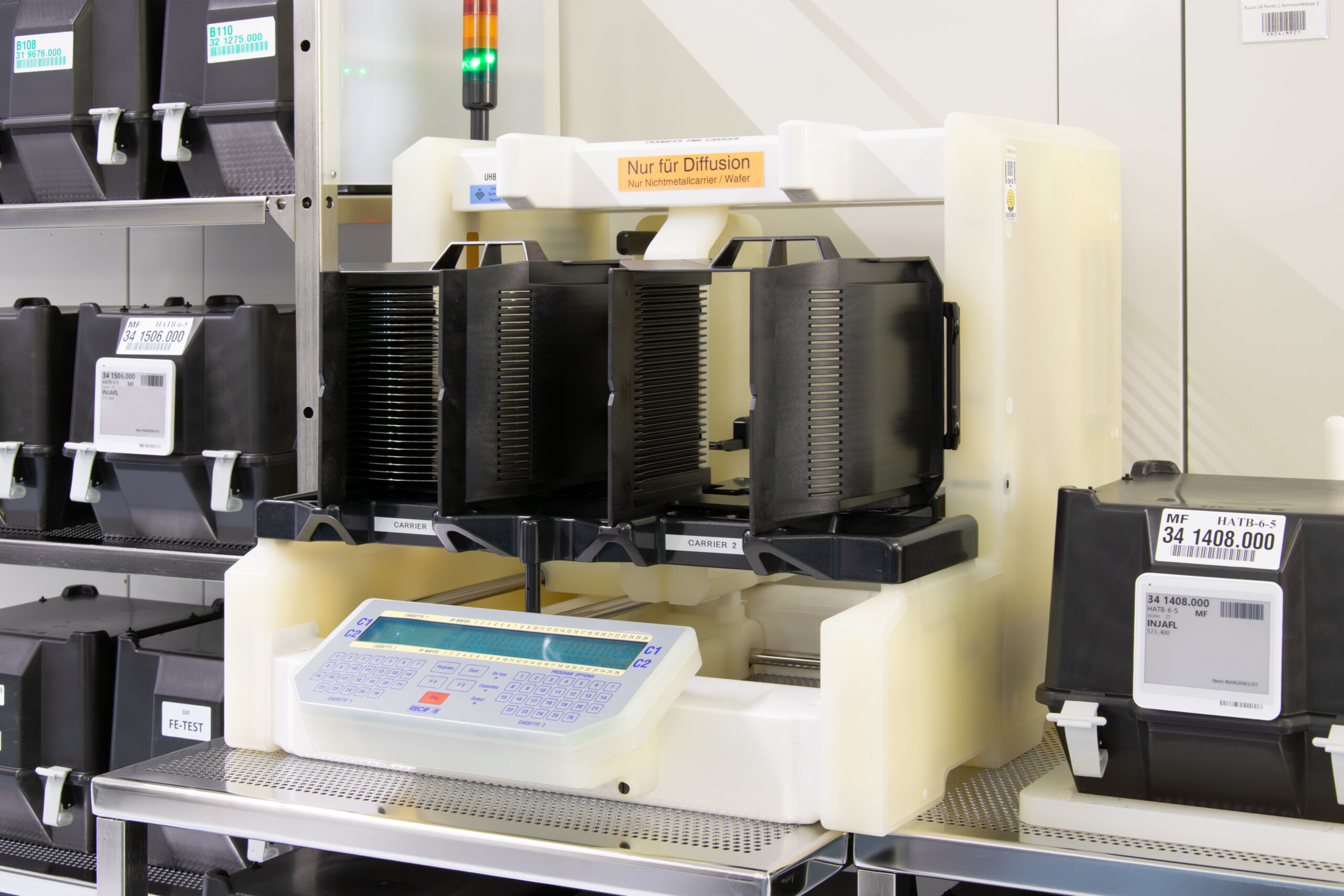

In the sensitive environment of a semiconductor cleanroom, end-to-end traceability of delicate materials is essential. Wafer boxes – specialized containers for protecting, transporting, and storing thin silicon wafers – play a central role in this process.

The wafers pass through numerous production stages, such as photolithography, ion implantation, diffusion processes, thin-film deposition, metallization, wet chemical processing, and dry chemical etching. Throughout the entire manufacturing process, as well as during handover to partners for further processing, the boxes ensure protection, safe transport, and secure storage of the wafers.

Until now, documentation has relied on paper-based documents, leading to the following limitations:

Transition to E-Ink Displays

Enhanced Transparency with RTLS and E-Ink Integration

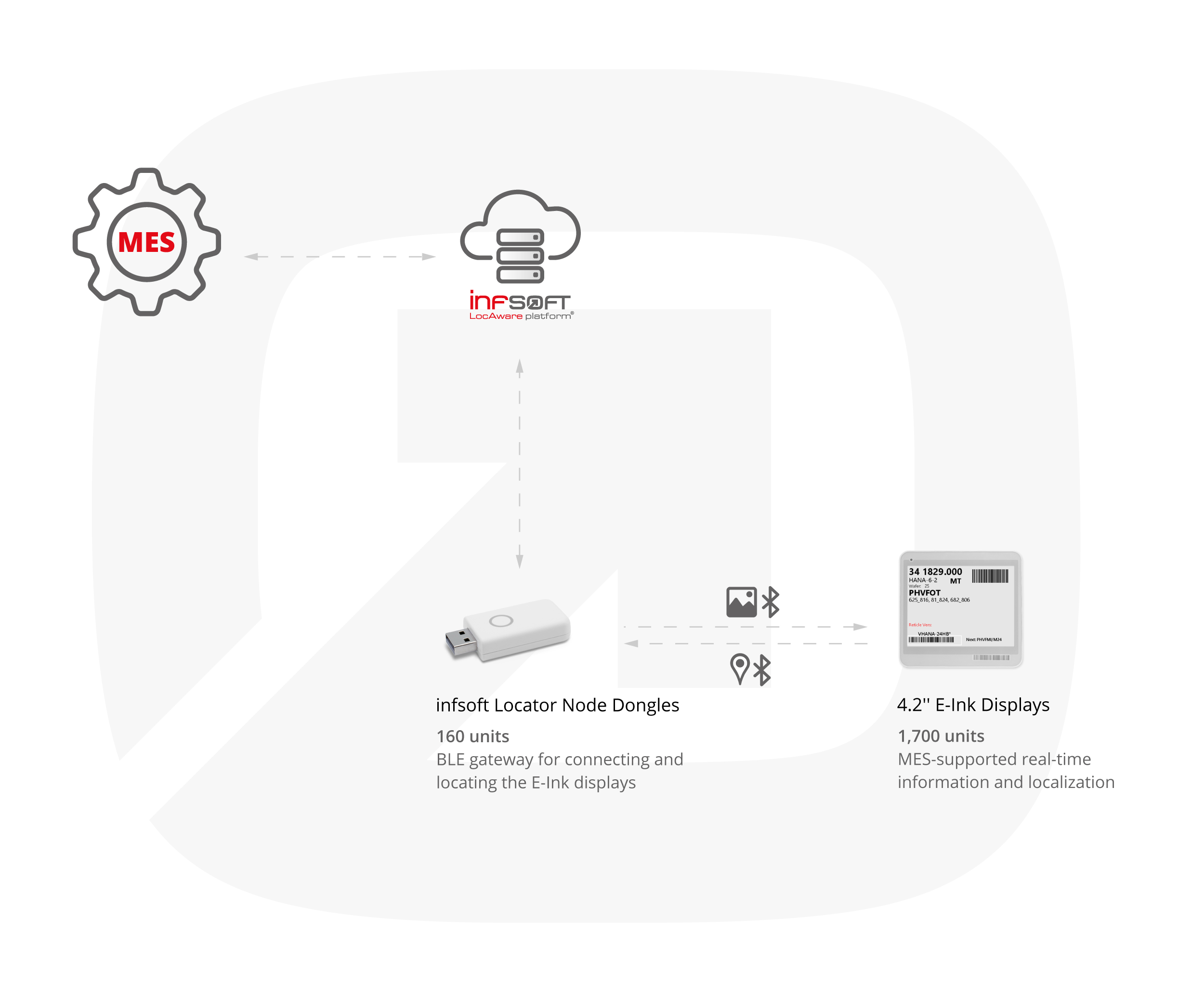

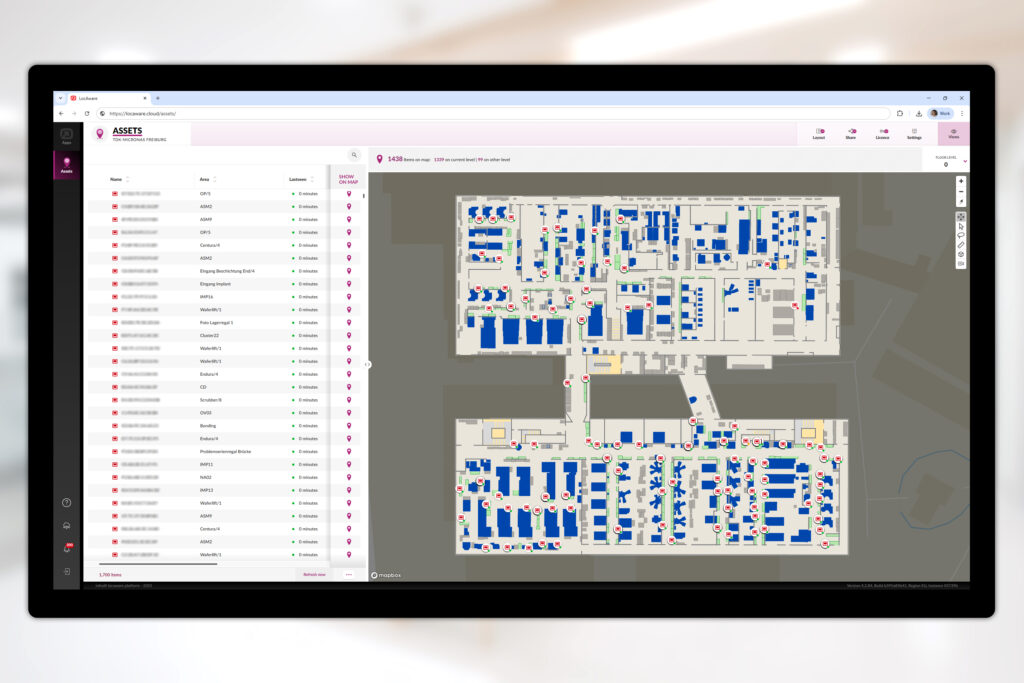

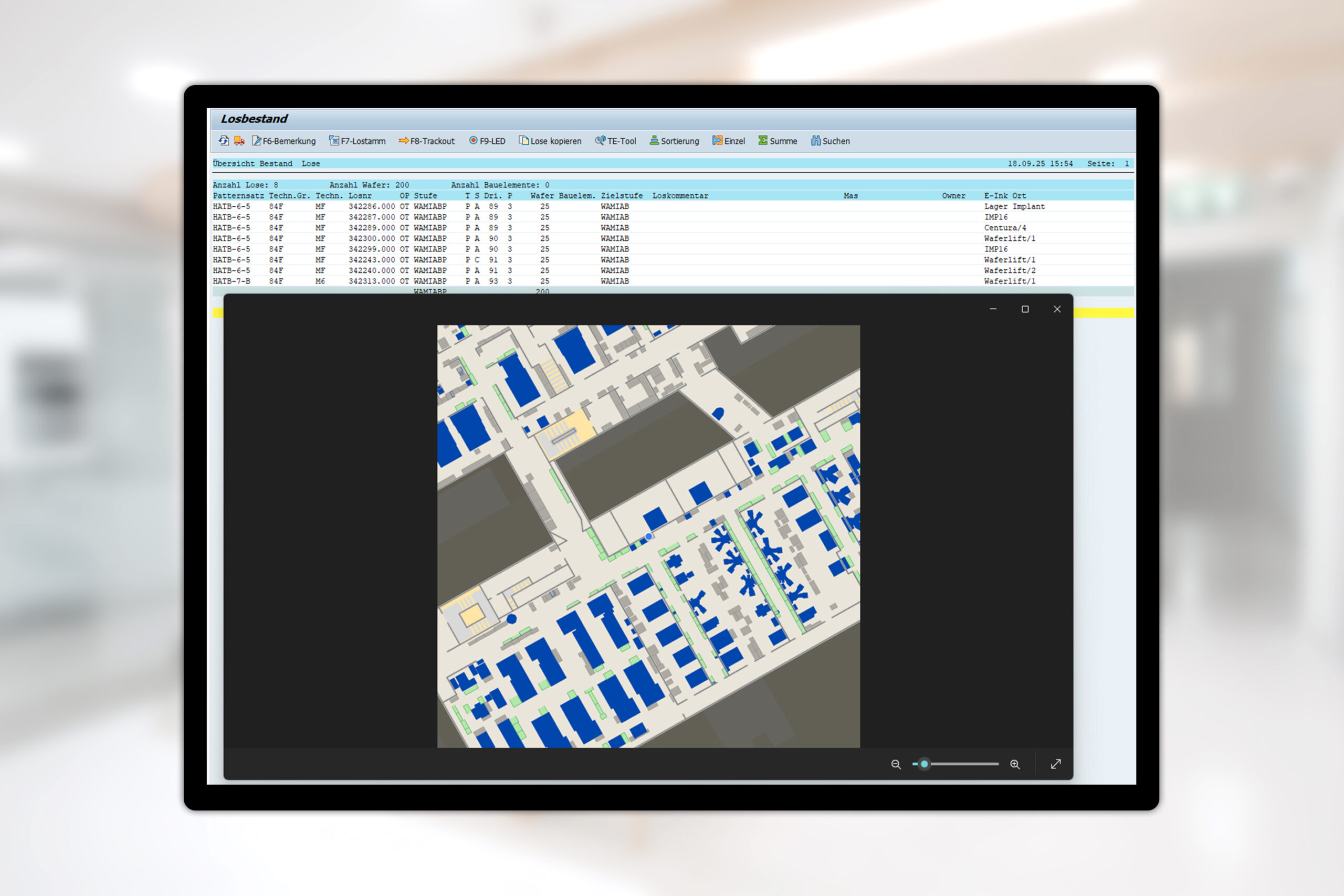

As part of the digitalization initiative, approximately 1,700 wafer boxes were equipped with 4.2″ infsoft E-Ink Displays and dedicated mounting brackets. These displays are managed via the infsoft LocAware platform®, which communicates bidirectionally with the Manufacturing Execution System (MES) of TDK-Micronas. Tracking and control of the E-Ink displays in the cleanroom are enabled by around 140 Locator Node Dongles, acting as gateways between the displays and the cloud platform.

Automatically generated templates with process-specific information are displayed on the screens. In addition, integrated LEDs and a digital map view enable rapid localization during search operations.

The Benefits:

The infrastructure is seamlessly integrated into the existing IT landscape, enabling continuous, automated real-time data communication.

The position data of the boxes is captured live and automatically transmitted back to the MES together with process-relevant information – including precise localization on a digital map.

The combination of E-Ink technology and Bluetooth Low Energy (BLE) also enables dynamic, automated display updates via infsoft Automation, through an MES interface, or manually if required.

Success Factors at a Glance

Sustainability Meets Digital Integration

The implementation of the digital tracking and E-Ink solution marks a major milestone on TDK-Micronas’ path toward Industry 4.0.

Cross-system networking, extensive automation, and real-time capabilities not only boost efficiency and transparency but also establish a future-proof foundation for further digitalization initiatives.

By fully replacing paper-based processes, potential sources of error are significantly reduced, resources are conserved in a sustainable manner, and a modern, future-oriented production environment is created – where digitalization, process quality, and environmental responsibility go hand in hand.

This approach supports efficient and transparent production control while ensuring compliance with high quality standards and continuously improving environmental performance.

With digitalization and automation, TDK-Micronas lays the groundwork for a future-ready production.

The combination of innovative technologies and sustainable processes strengthens competitiveness and creates optimal conditions for continued growth in the digital age.

Feel free to contact us for a personalized consultation regarding a similar project.

Success Story as PDF