With infsoft Lead Time Tracking, processes can be documented and controlled. The definition of triggers and connected actions also enables the automation of individual work steps.

infsoft Lead Time Tracking increases process transparency and enables data-driven analyses. By implementing the solution, operating costs can be reduced significantly, bottlenecks and downtime can be avoided, and on-time delivery to customers is ensured.

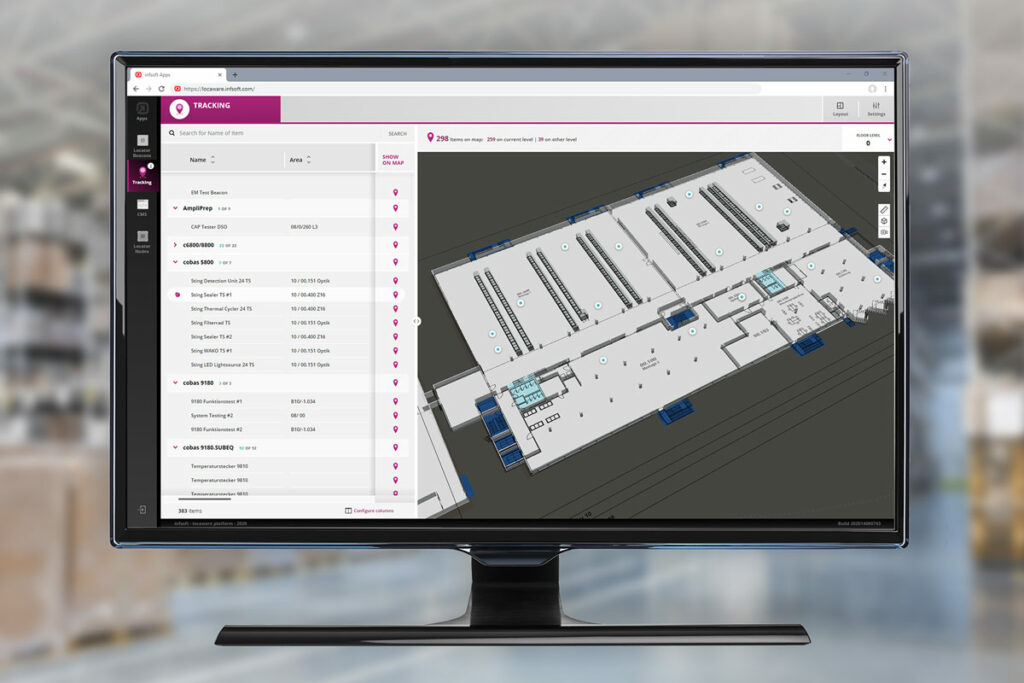

By tracking assets, for example in industrial manufacturing, the location of a tracked object can be established and accessed at any time. Based on the position data, lead times can be recorded and processes can be evaluated and optimized. In addition, real-time tracking and the definition of individual triggers enable the automation of processes.

Real-Time Asset Tracking

As part of infsoft Lead Time Tracking, the objects to be tracked are equipped with efficient Bluetooth Low Energy hardware (beacons). The beacons are characterized by low maintenance requirements and high durability. The position data is processed and displayed in infsoft’s powerful software. The solution can also be integrated into third-party systems.

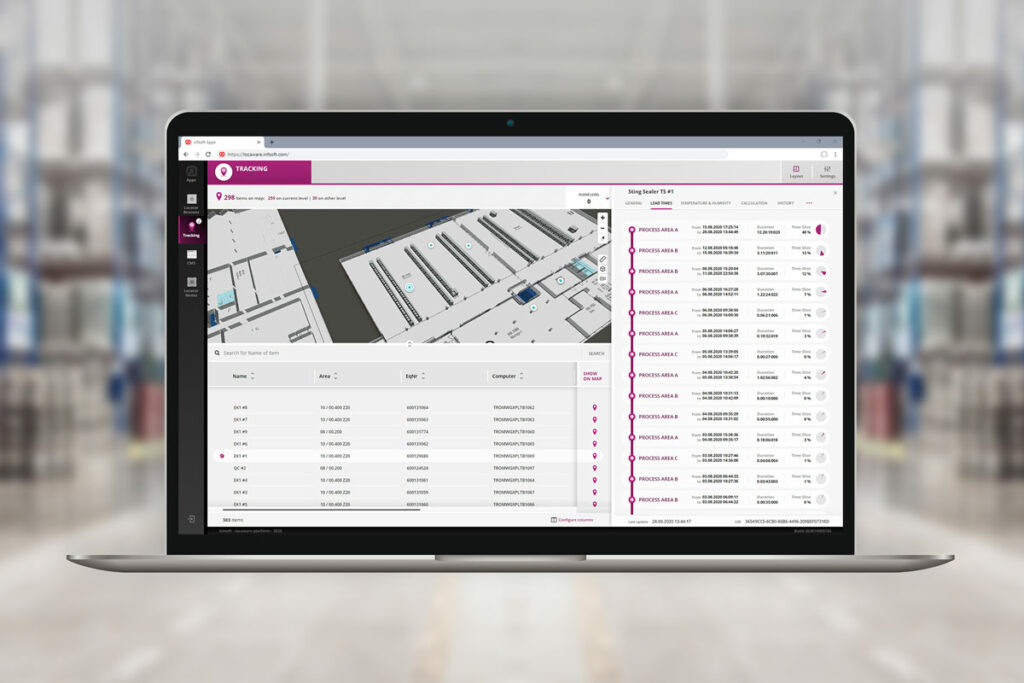

With infsoft Lead Time Tracking, it is possible to reliably determine when an object reaches or leaves a particular workstation and how much time each work step consumes. The recorded lead times can then be compared with the predetermined target times directly in the application.

In addition, the system displays available capacities at the individual workstations and, if necessary, shows options for temporary storage of the goods if the relevant workstation is already fully occupied.

Process Automation

With infsoft Lead Time Tracking, processes along the process chain can be automated by defining individual conditions and resulting actions. The triggers can, for example, be time-based or geo-based (geofencing). Other types of triggers can also be defined flexibly for the particular use case. In addition, the conditions can be linked to each other in any way.

In the context of lead time measurement, it is possible to register when an object arrives at a workstation and when it leaves it again. This technology can also be used to send automatic notifications, for example if an order is at risk of falling behind schedule.

Instead of beacons, E-Ink display beacons can also be attached to objects. These can be located just like the conventional beacons and can also be labeled. The displays can then be used to provide information such as order numbers and work instructions, for example. Moreover, the displays can be updated automatically based on predefined conditions.

Application Fields Outside of Industrial Environments

infsoft Lead Time Tracking is particularly in demand in industrial environments but can also be used effectively in other industries. For example, this solution can be used to track processes in the retail sector, to document the resources and time spent in medical facilities, or to automate processes in office buildings.

For more information on “infsoft Lead Time Tracking” including some cost examples, interested parties can visit www.infsoft.com/lead-time-tracking.