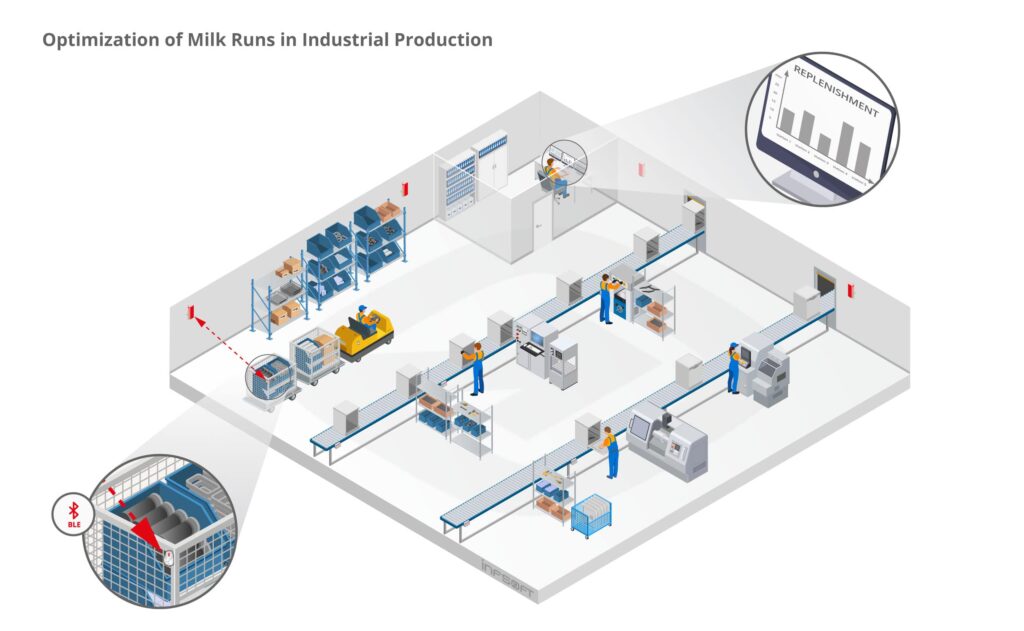

Tracking solutions and analysis functionalities enable dynamic and efficient milk runs in production.

AT A GLANCE

- real-time tracking of components in manufacturing

- demand-driven and dynamic milk runs

- analysis of motion profiles

PROBLEM DEFINITION

In production, only a limited number of components are stored at the assembly stations. If these parts are not replenished in time, expensive delays in the process flow occur. However, unnecessarily frequent deliveries to the workstations are also not cost-effective.

In many production processes, for example when there is a large number of variants, fixed time intervals for the milk runs are not possible or reasonable.

SOLUTION

Ideally, the routes and departure times of the milk runs should be dynamic and demand-driven. Different technologies enable optimal delivery to the assembly stations and at the same time optimal capacity utilization of the tugger trains.

One way to realize this is a connection to the ERP system. Based on incoming orders, the material requirements can be determined and a delivery of components can be initiated automatically.

Another possibility is the use of tracking solutions and geofences. In this way, for example, orders can be triggered when a particular zone is entered by a tugger train or based on how often certain areas are frequented.

For analysis purposes and process optimization, the position data obtained from the tracking solution can be visualized and evaluated in an analysis software. Among other insights, the time it takes to restock a shelf can be measured and travel distances and times can be monitored.

TECHNICAL IMPLEMENTATION

infsoft Locator Nodes are installed at regular intervals throughout the site while Bluetooth Low Energy beacons are attached to the vehicles or boxes containing components that are being tracked. The beacons transmit signals which are received by the Locator Nodes. The data is then forwarded to the infsoft LocAware platform®, where the position is determined.

By using infsoft Automation, triggers – e.g. the incoming of a new order or the detection of a tugger train in a certain area – can be defined. The occurrence of such a situation then automatically triggers an action such as ordering new components.

In infsoft Analytics, the collected data can be visualized in comprehensive and personalized dashboards.