Efficient sample and cold storage management in laboratories requires a clear overview of freezer compartment occupancy, project assignments, and equipment status. With infsoft E-Ink Displays, this information can be visualized directly at freezers or cold storage units. Laboratory staff can instantly see which compartments are available, which samples or projects are assigned to them, and who is responsible for inventory and equipment – without time-consuming queries in the laboratory information system. The result: increased efficiency, reduced cold storage opening times to minimize temperature fluctuations, lower error rates in sample storage, and smoother laboratory operations.

AT A GLANCE

- Real-time visualization of freezer compartments and cold storage units, including projects and equipment status

- Display of responsible staff for inventory and equipment

- Energy-efficient, low-maintenance E-Ink Displays

- Seamless integration with existing laboratory information systems

- Minimized cold storage opening times and reduced temperature fluctuations

PROBLEM DEFINITION

In large laboratory environments, it is often unclear which freezer compartments or cold storage units are currently occupied or available, which projects are assigned to each compartment, and what the status of the equipment is. In addition, there is often no transparent overview of the staff responsible for inventory and equipment. This makes it difficult to use resources and cooling capacities efficiently, slows down laboratory workflows, and increases the risk of errors in the storage and management of sensitive samples and materials.

SOLUTION

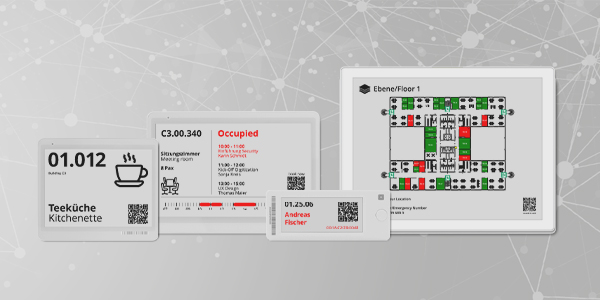

With digital labeling, the availability of freezer compartments and walk-in cold storage units can be visualized in real time. Each compartment is displayed clearly, including the assigned samples and projects, current equipment status, and the staff responsible for inventory and equipment. The BLE technology enables seamless integration with existing laboratory information and management systems, while energy-efficient E-Ink displays provide a low-maintenance, easy-to-read solution directly at the device. This approach optimizes the use of cooling capacities, streamlines laboratory workflows, minimizes cold storage opening times, and reduces temperature fluctuations. At the same time, transparency in the laboratory is increased, significantly lowering error rates in sample storage.

TECHNICAL IMPLEMENTATION

For implementation, infsoft Locator Node Dongles are used in combination with energy-efficient infsoft E-Ink Displays. Each freezer compartment is equipped with an E-Ink Display, which is regularly synchronized with the infsoft LocAware platform® via the gateways – the infsoft Locator Node Dongles. An interface between the infsoft LocAware platform® and the laboratory management system enables the exchange of various data, including the status of individual compartments as well as information on assigned projects, responsibilities, and equipment conditions.

Data processing and management are handled entirely through the infsoft LocAware platform®. Compartment occupancy, project assignments, and status information from existing laboratory information systems are automatically imported and updated in real time. Through defined workflows, changes in status – such as a freed compartment or an updated project assignment – can be immediately transmitted to the corresponding E-Ink displays.

The E-Ink technology enables highly energy-efficient labeling of freezer compartments and cold storage units while ensuring excellent readability, even under challenging lighting conditions. Thanks to the wireless BLE communication, the displays can be flexibly retrofitted without any changes to the existing laboratory infrastructure. Additionally, the E-Ink displays are available in various sizes and formats, allowing them to be optimally adapted to different compartment sizes, information volumes, and application areas.