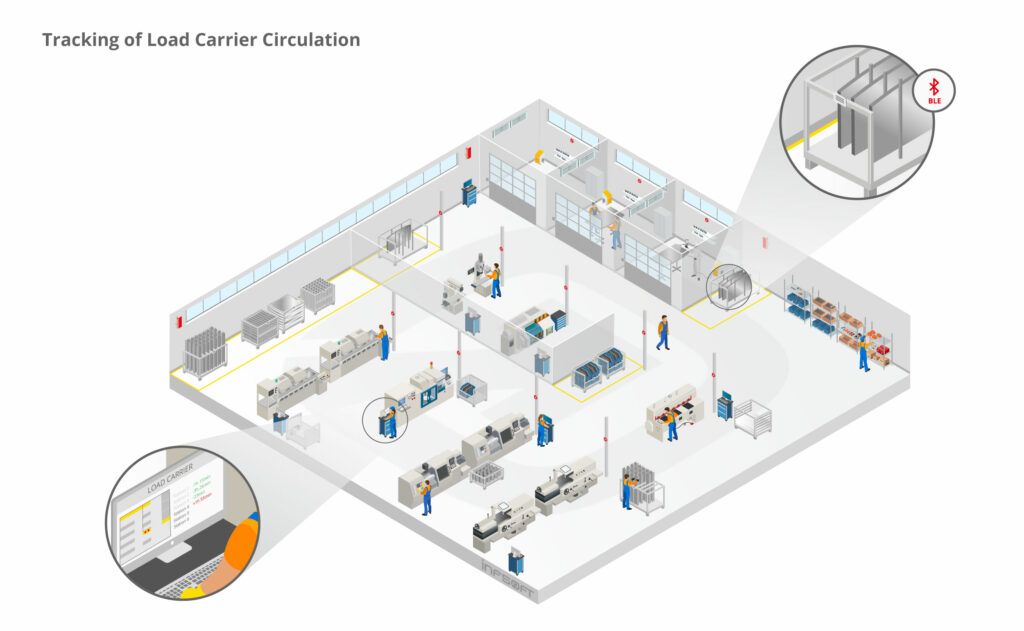

Tracking of load carrier circulation supports on-schedule completion of orders.

AT A GLANCE

- tracking of load carriers along the process chain

- comparison of target and actual processing times of each work process

- automatic generation of transport orders to the next workstation or a suitable buffer space

PROBLEM DEFINITION

Completing orders on time is important in any industry to ensure smooth processes and customer satisfaction. The delay in one work step can have a negative impact on the schedule of the entire order and following orders.

SOLUTION

A tracking system and the measurement of lead times support the company in completing orders on time and meeting their deadlines.

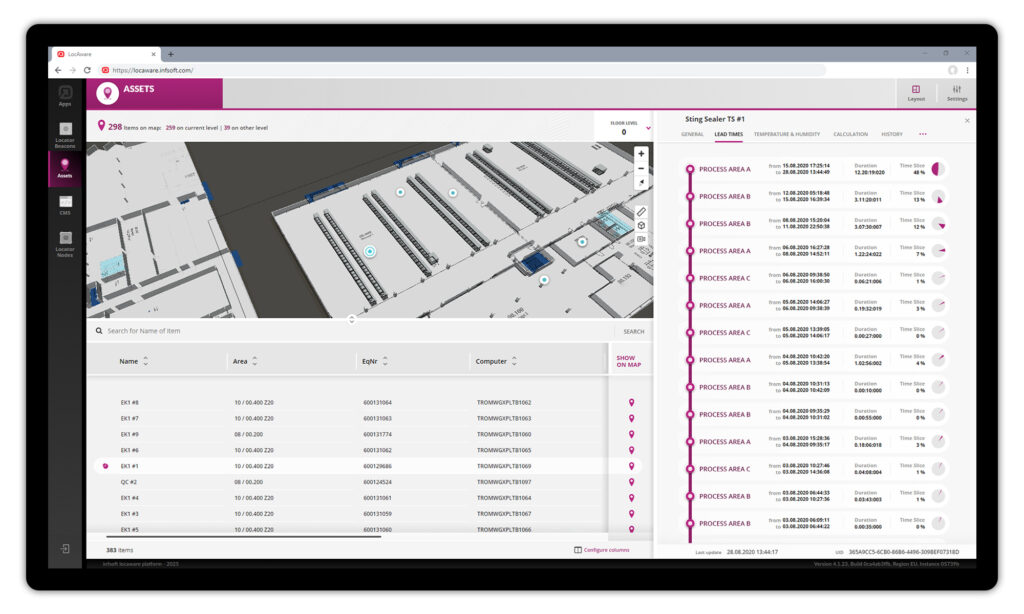

Firstly, the solution ensures that the right load carrier is available at the right time for each order. Then, along the process chain, the position of load carriers and the goods located on them, which are assigned to an order, can be determined at any time and accessed in a web-based application. In addition, with this solution, the working time at the individual workstations can be determined and a comparison between the target time and the actual time can be made. Any delays in the process and resulting shorter available working times at later stations can also be viewed at any time.

Automatic generation of transport orders is possible through the connection to the transport order system. When the work has been completed at a workstation, an employee can confirm this. The transport order is then created automatically, taking several factors into account. If the next workstation is free, the order is delivered there. If there is currently no space at the workstation, then the order is automatically assigned the most suitable buffer space (nearby, suitable weather protection class, etc.) for the interim period.

A special case that may occur is that part of the order has a defect and needs to pass through past workstations again. In such a case, the order is split and merged again later.

TECHNICAL IMPLEMENTATION

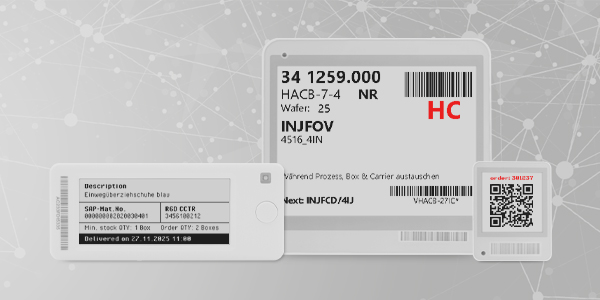

The load carriers are equipped with infsoft E-Ink Display Beacons. infsoft Locator Beacons and infsoft Locator Node Dongles will be installed throughout the site. The infsoft Locator Beacons receive the signals from the E-Inks and send them to the Locator Nodes. From there, the data is forwarded to the infsoft LocAware platform®. There, the positioning and intelligent processing of the data takes place.

In turn, the E-Ink displays can be described and updated via the Locator Nodes. This is possible either by manual input or alternatively automatically by defining individual triggers in infsoft Automation.

Current and past locations of the load carriers can be viewed in infsoft Assets. In addition, as part of infsoft Lead Time Tracking, the time required for the individual work steps and deviations from the target time can be displayed.