In industrial environments, a geobased logic engine makes a decisive contribution to ensuring efficient operating processes and the best possible utilization of workstations.

AT A GLANCE

- server-based vehicle localization in real time

- capture workload and status of equipment

- analysis reports based on historical data

PROBLEM DEFINITION

Modern production processes are largely automated from order entry through processing to manufacturing. However, a purely sequential work structure is often used and the employees wait for the completion of a single process, which in turn represents an inefficient use of manpower. If activities are processed one after the other, waiting times occur. This results in higher labour costs and reduced competitiveness.

SOLUTION

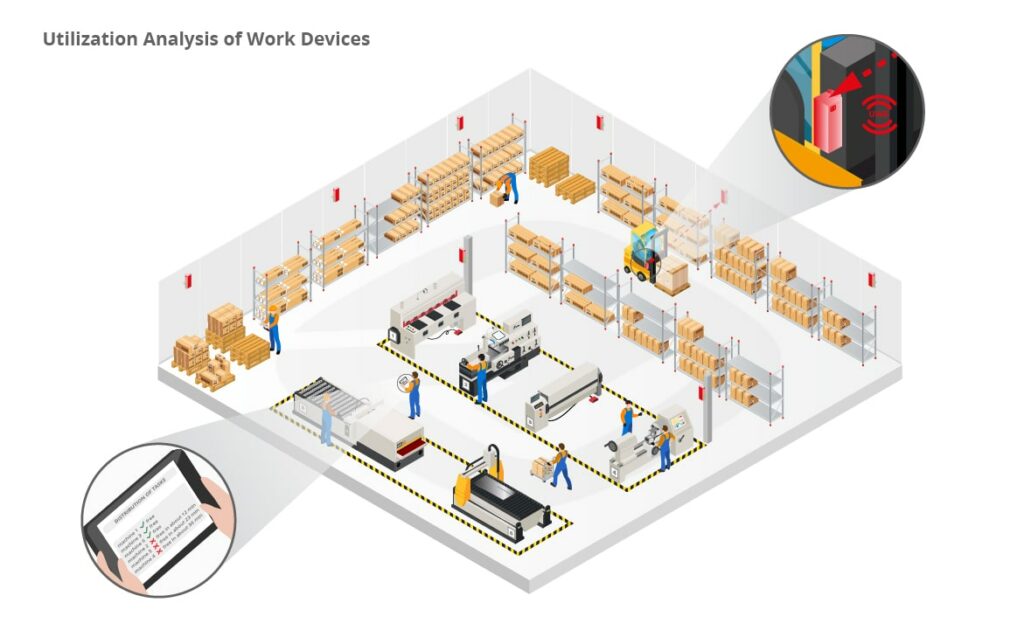

The use of a geobased Logic Engine solution increases the efficiency of operational processes and ensures optimum utilization of all available machines. In real time, the locations of the work equipment located on the site as well as its occupancy and status can be viewed at any time. This data is made available to the infsoft LocAware platform®, which controls the placing of orders with employees. With infsoft Machine Learning, the platform has algorithms at its disposal which control the awarding of contracts based on empirical values and individual parameters according to efficiency-optimised conditions.

The linking of the systems enables a significantly more efficient work organization of the employees and a more even utilization of the workstations. After a successfully completed task, the employee is immediately shown the next job. This was previously identified by the Machine Learning Tool as the order that is most time-efficient to complete. Additional information such as the locations of the tools are provided at the same time.

A successful implementation of such a solution means lower personnel costs, time savings and ultimately a higher competitiveness of the company. Furthermore, reports based on historical activities can be created, which support the management in investment or control decisions. For this the already existing ERP and management support systems can be used, which are extended by the geobased data.

TECHNICAL IMPLEMENTATION

In the production area, infsoft Locator Nodes are installed and connected to the power grid. Machines and plants are equipped with infsoft Locator Tags with Ultra-wideband (UWB) module, which measure the distance (Time of Flight, ToF) to the Locator Nodes. The data is sent back to the Locator Nodes and from there transmitted to the infsoft LocAware platform®. In case of application, the infsoft LocAware platform® also contains algorithms which function according to the principle of machine learning. Here infsoft Machine Learning takes over the order control and coordination according to the parameters defined by the management and forwards it to the Workflow Manager. The ERP software and other operational systems already available in the company can be supplemented with geo-based data. The operating parameters can thus be evaluated in the usual way.