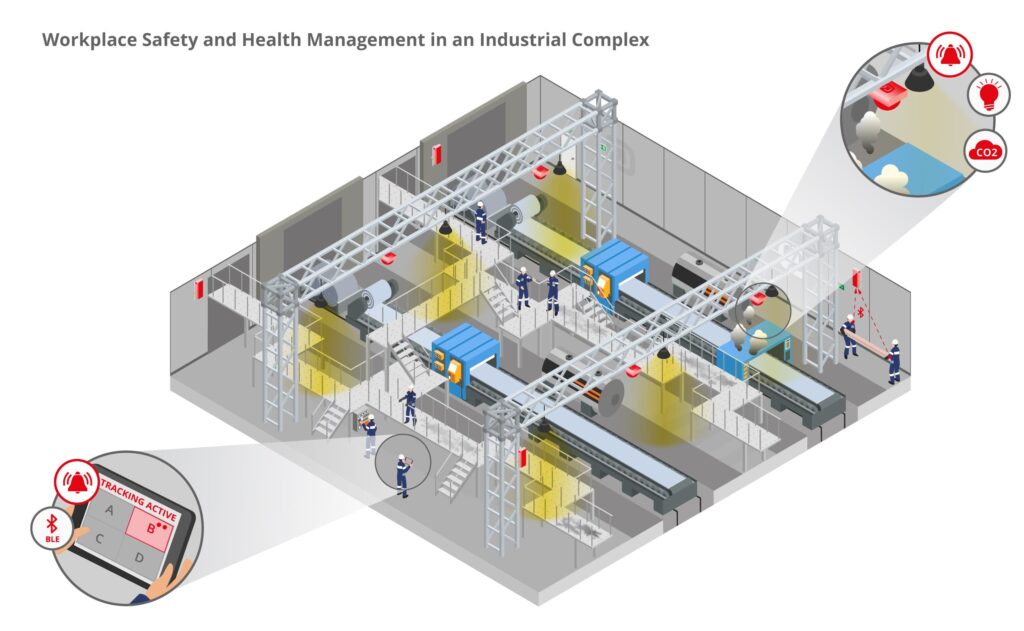

In large industrial complexes, a monitoring and tracking solution can ensure workplace health and safety.

AT A GLANCE

- server-based positioning of employees in case of danger

- monitoring of working conditions (CO2 content, lighting conditions)

PROBLEM DEFINITION

Employees in large industrial areas often perform physically demanding activities and are frequently confronted with potential sources of danger. In such environments it is particularly important to create health-promoting and safe framework conditions. Environmental conditions such as temperature, air quality and lighting conditions as well as evacuation management in case of danger are important influencing factors which can guarantee or endanger a safe and healthy working environment.

SOLUTION

A solution for realizing employee tracking in the event of danger, combined with a working condition monitoring system, offers suitable measures for occupational health and safety management.

The tracking system shows the position of the factory employees on a map as soon as it is activated in an emergency. The plant management sees whether any persons are still in the affected zone and can evacuate them safely and quickly if necessary. A back channel for contacting endangered persons is optionally possible.

A condition monitoring system permanently checks air quality and lighting conditions and controls third-party systems as required to continuously ensure optimal working conditions.

TECHNICAL IMPLEMENTATION

infsoft Locator Nodes and infsoft Sensor Tags are installed on the industrial site. The Sensor Tags measure the illuminance and CO2 content in the environment and send the scan data to the Locator Nodes via Bluetooth. The latter then transmit the data to the infsoft LocAware platform®. In the Automation Engine, status information is linked to conditions, so that management systems can automatically trigger actions such as the adaptation of climate control when limit values are exceeded.

Each employee is equipped with a beacon – either in a safety helmet or in the form of an ISO card. The beacons send signals which are received by the infsoft Locator Nodes and forwarded to the infsoft LocAware platform®. In case of an emergency, the position can be determined here and can be displayed to safety personnel via an application.