An asset tracking system enables better monitoring and control of manufacturing processes as well as optimized production flows.

AT A GLANCE

- real-time tracking of components along the production line

- monitoring of process steps and lead times

PROBLEM DEFINITION

In manufacturing, components travel considerable distances on the production line before they reach their final destination and a production order is completed. Without digital solutions, there is little visibility into the individual manufacturing steps, and the risk of production downtime and increased operating costs increases.

SOLUTION

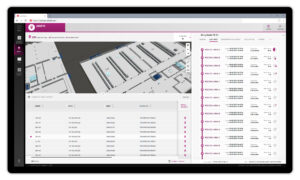

With a BLE-based tracking system, manufacturing companies gain a complete view of the manufacturing process on the assembly line. Whether it’s tracking all the individual parts being assembled or monitoring the time it takes to complete the process, operators gain comprehensive insights and can respond to delays in a timely manner.

All parts needed for the manufacturing process are identified using Bluetooth tags and can then be located within the facility in real time. It is possible to track how much time products have spent at each workstation, as well as check the processing status of an order and identify missing parts or disruptions in the production process. In addition, the unauthorized removal of products can be prevented. As soon as a process step is completed, the status can be automatically updated in the system, and involved employees can receive notifications if necessary. The asset tracking solution significantly reduces the time required to check each finished item as it leaves the production line.

TECHNICAL IMPLEMENTATION

The boxes in which the production parts are stored are equipped with Bluetooth Low Energy (BLE) tags. infsoft Locator Nodes, which require network and power connectivity, are installed in the manufacturing hall. The Locator Nodes receive the Bluetooth signals from the BLE tags and forward the data to the infsoft LocAware platform®, where the information is intelligently processed.

Alternatively, infsoft Locator Beacons Smart Plug can be used, which are connected to free power sockets. This option significantly reduces the number of Locator Nodes required. In this case, the transmitted signals from the BLE tags are received by the Locator Beacons and sent to the platform via a Locator Node.

The web-based infsoft Assets software provides visibility into current and historic locations of manufacturing parts. Based on infsoft Lead Time Tracking, the time required for each process step can be tracked, and target and actual times can be compared. Automated notifications can be configured via infsoft Automation.