Maintenance work on aircraft and their components is important to keep the aircraft safe and ready for daily flight operations. Efficient solutions for maintenance work can significantly reduce downtimes.

AT A GLANCE

- 2D/3D building maps

- localization of toolboxes in real time

- analysis reports based on historical data

PROBLEM DEFINITION

In aircraft maintenance, delays lead to massive follow-up costs. A cause that often leads to inefficient maintenance process is inadequate tool management. Since the for special tools required for aircraft are expensive and are therefore only available in small quantities, aircraft mechanics are often busy with finding the right work material for the next maintenance step. This is made more difficult by the fact that tools often cannot be returned to the storage location quickly enough or several storage locations can be used.

SOLUTION

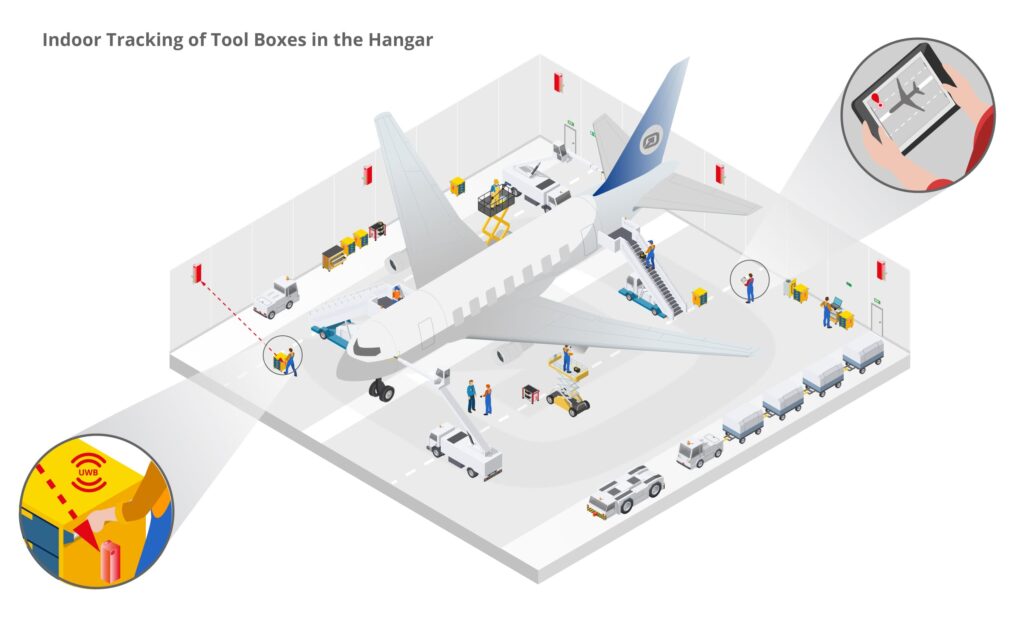

A precise tracking solution can ensure smooth aircraft maintenance operations. The individual tool trolleys are tracked using indoor tracking based on Ultra- (UWB) and located on a digital map, on which every mechanic can access a terminal or mobile via an app.

A tracking solution based on Ultra-wideband (UWB) provides precise position data of Toolboxes. This provides a central overview of the locations of the various boxes. The tracking solution contributes decisively to a safe and efficient operation in the hangar and ensures the best possible utilization of the equipment. At any time are the locations of the toolboxes and information about the loaded tools in a web interface for the mechanics.

TECHNICAL IMPLEMENTATION

infsoft Locator Nodes are installed throughout the hangar and connected to the power grid. The tool trolleys are equipped with infsoft Locator Tags with UWB module. The Locator Nodes scan their environment for the signals sent by the Locator Tags and send the recorded data to the infsoft LocAware platform®. Here they are collected in a database and sent to a web interface. Using an app or browser application, the mechanics can access the data and see the location of the toolbox on a map with an accuracy of less than 30 centimetres.