In automotive production, the use of a tracking system based on Ultra-wideband can ensure that supplying material to the assembly workstations runs smoothly.

AT A GLANCE

server-based solution:

- 2D/3D plan of real-time localization of tugger trains

- location overview on digital map including status information

client-based solution (smartphone app):

- positioning of driver

- navigation & messages concerning the route

PROBLEM DEFINITION

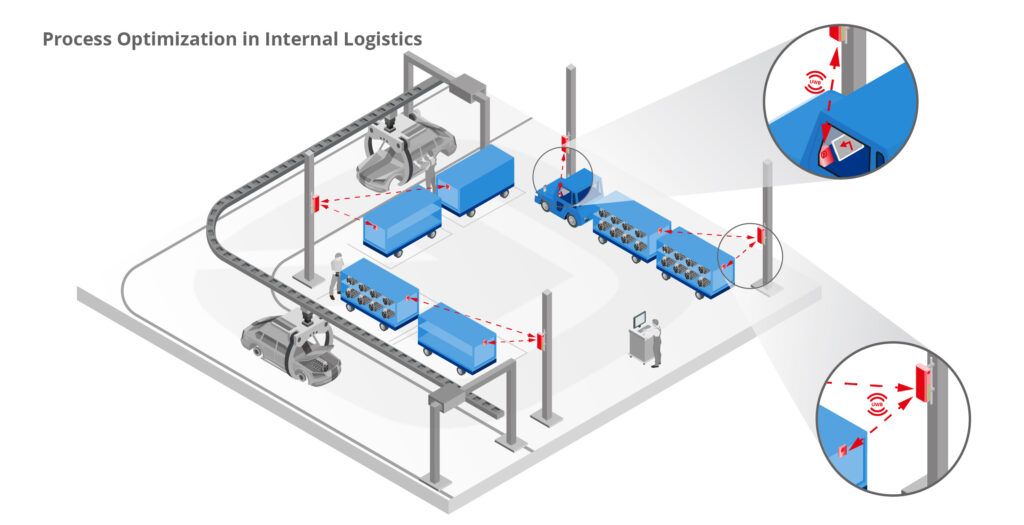

A needs-oriented material supply is an important part of the serial production of vehicles. Automobile and commercial vehicle manufacturers usually use tugger trains with just-in-sequence trolleys for this purpose. In these special containers, the various components are brought to the assembly line in the correct order. When providing a full just-in-sequence trolley, a corresponding empty container is picked up. Delays of the tugger trains sometimes lead to the fact that the required time of supply of a just-in-sequence trolley cannot be met. This results in a stop of the assembly line and considerable additional costs.

SOLUTION

A precise tracking solution based on Ultra-wideband can ensure a smooth production process. Expensive production stops due to late-arriving just-in-sequence trolleys can be prevented through real-time location tracking of the just-in-sequence trolleys and tow tugs. The position of the tugger trains as well as information on the loaded materials is displayed on a digital map which is accessible via web interface.

Additionally, the drivers of the tow tugs can view the position data on a mobile device and can check at any time whether they are still on schedule. Automatic calculations determine whether a material supply will be delayed. Thus, countermeasures can be initiated in due time. The driver receives messages via smartphone, for example warnings when he is delayed, route descriptions or changes.

TECHNICAL IMPLEMENTATION

If a precise localization (10-30 cm) with low latency is desired, server-based indoor positioning based on Ultra-wideband (UWB) is the right choice. For this purpose, infsoft Locator Nodes are installed on the premises. The tow tugs and just-in-sequence trolleys to be tracked are equipped with battery-powered infsoft Locator Tags, which measure the distance to the Locator Nodes. The position data are transmitted to the infsoft LocAware platform® via internet connection, where the position of the tow tugs and just-in-sequence trolleys is calculated and the data are transferred to an output medium.

In the case of an additional client-based indoor localization, the Locator Tags exchange the data via Bluetooth or USB interface with the mobile device of the driver. The position is calculated and displayed on the smartphone. The driver receives directions and, if necessary, messages concerning his route.