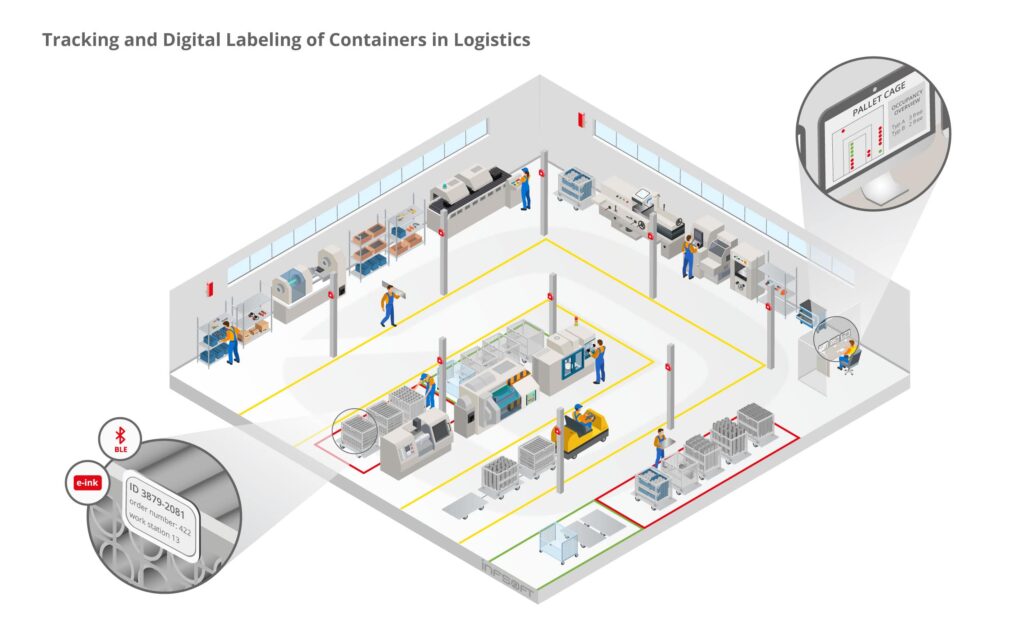

Tracking and automatic, digital labeling of containers can facilitate processes in logistics environments.

AT A GLANCE

- tracking of containers in logistics

- digital information display

- automatic status changes through geofencing

- assignment of tasks to employees

PROBLEM DEFINITION

Automation and digitization lead to more efficient processes in logistics. Most importantly, this saves time and costs and enables early identification of bottlenecks and other issues.

SOLUTION

A tracking solution can increase the efficiency of logistical processes. Therefore containers (small load carriers, pallet cages, etc.) are equipped with E-Ink Display Beacons. These can be located and labeled by the system.

The transported goods can be allocated to the containers via an interface to the ERP system. Tracking the containers enables the user to track material flows within the site. The position data and the lead times can be accessed via a web interface or mobile application. In addition, the E-Ink displays show the next work step or the next work station.

Geofencing can be used to automatically determine and change the status of containers based on their location. This way, the user gets an overview of available containers and those that are in use. The content on the E-Ink displays can also be automatically updated based on their location.

Furthermore, orders (e.g. for material carts) can be assigned to a staff member in charge using infsoft Workflow.

TECHNICAL IMPLEMENTATION

Containers are equipped with E-Ink Display Beacons. The beacons emit signals, which are received by infsoft Locator Beacons and forwarded to an infsoft Locator Node. From there, the information is sent to the infsoft LocAware platform® where the position is determined. The allocation of goods to containers and E-Ink Display Beacons is realized via an interface to the ERP system.

The E-Ink displays are being described via the infsoft Locator Nodes. An automatic update of the labels can be realized via infsoft Automation. Position data and lead times are displayed and visualized in infsoft Tracking. Work orders can be assigned to employees via infsoft Workflow.