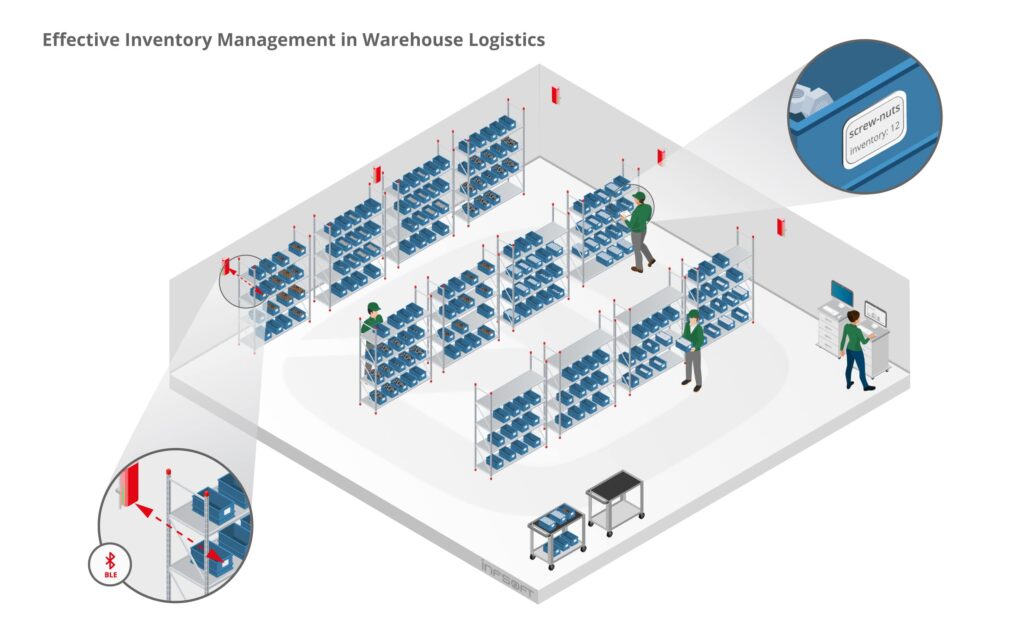

Tracking and digital, automatic labelling of containers with components in stock support the optimal ordering policy.

AT A GLANCE

- Localization of goods within the warehouse

- Information about the inventory (department, date, value etc.)

- Utilization analysis of the inventory

PROBLEM DEFINITION

Warehouses are the heart of supply chains around the world. It is therefore essential that warehouse organizations are operated in the most efficient and error-free environment possible. Information on location and the consumed and available quantity of stored items is critical to determining order frequency and quantity. Inefficient processes or incorrect information are associated with the creation of unnecessary costs and/or delays. There are a variety of classic methods available for inventorying inventories, but all of them involve either a high level of organizational effort or inaccuracies.

SOLUTION

With the E-Ink-Beacon Displays it is possible to organize an automated inventory management without interrupting the normal operation for a manual inventory. The displays show a QR code or barcode, which can be scanned when goods are removed. The removed quantity of goods is registered by the ERP system and the remaining quantity is directly shown on the E-Ink-Beacon display. The digital registration allows an order to be triggered as soon as the order limit is reached.

In larger warehouses it is also possible to use the locating function of the E-Ink-Beacon Displays. This allows specific goods to be clearly located and targeted. This not only makes it easier to train employees, but also enables the automation of logistics.

Another advantage is the digital coding of the E-Ink-Beacon Displays. This can be done centrally and efficiently via the ERP system. Raw materials are also saved.

TECHNICAL IMPLEMENTATION

Containers with components are equipped with E-Ink Display Beacons. To locate the containers, infsoft Locator Nodes receive the Bluetooth signals from the beacons and send the data to the infsoft LocAware platform®. Here the data is processed intelligently and the position is determined. This can then be viewed on a digital map via an app or browser application.

The labelling of the E-Ink-Display beacons can be realised via an interface with the ERP software. The content is transferred via Bluetooth from an infsoft Locator Node to the E-Ink Display to be labeled. The information on the display can be automatically adjusted by the infsoft Automation Engine as soon as the inventory changes.

The company is given access to the data via a browser application. In addition, the infsoft Analytics Tool also allows the historical data to be retrieved, evaluated and compared with the real-time data at any time. This allows the user to see at a glance which areas are working at what time of day and to what extent.