Punctual production supply in production industries can be facilitated by tracking tugger trains and applying a machine learning system.

AT A GLANCE

- tracking and navigation of tugger trains

- forecasts with machine learning

- automated generation of instructions and warnings

PROBLEM DEFINITION

Especially in the automotive industry, a considerable number of components is delivered just-in-time. There is very low to no warehousing for these goods and they arrive at the production hall only shortly before they are needed at the assembly line. Therefore, even short delays can result in production stops and extensive costs.

SOLUTION

Including a tracking solution and a machine learning tool in the tugger train management contributes to the punctual arrival of components at production. Furthermore, it enables early warnings when delays and production stoppages are impending.

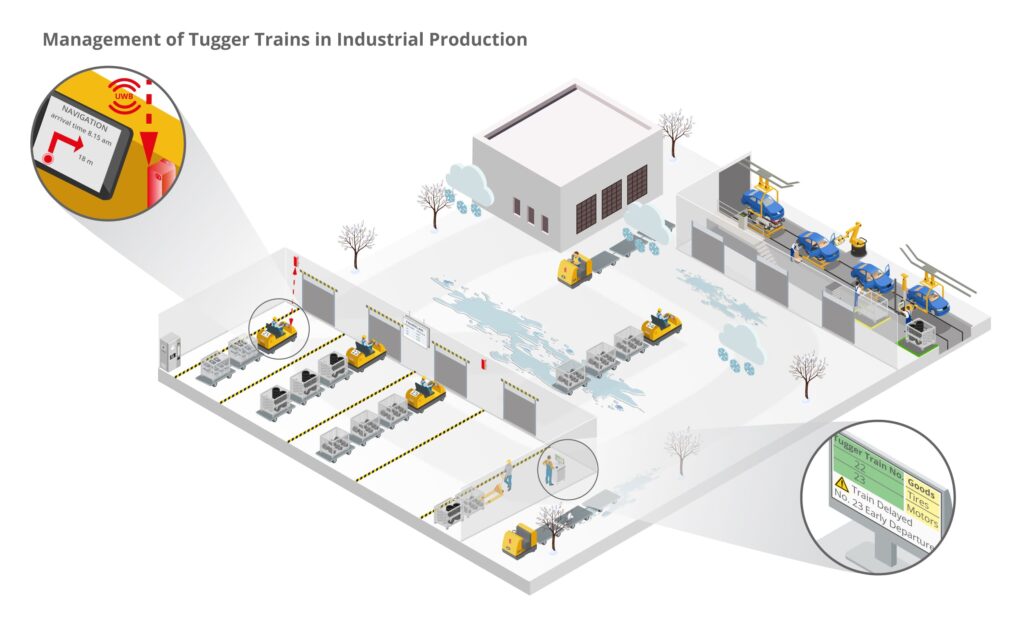

With the just-in-time form of procurement, suppliers deliver components to the production site soon before they are assembled. Tugger trains then transport the parts to the assembly line right on time. In order to support the punctual arrival at the destination, the departure times of the tugger trains are planned precisely and displayed on a digital information board. Additionally, the drivers receive detailed route instructions on a display inside the vehicle. A foreman at the tugger train station will have access to a task overview, as well as to the current positions of all tugger trains, visualized on a digital map. This enables him to intervene as soon as he notices deviations from the planned process flow.

Various factors, like the weather for example, can influence the driving time of tugger trains and impede the timely arrival of components at the assembly line. A machine learning tool forecasts the probability of delays and resulting production stoppages reliably. Is the tugger train likely to be delayed, the driver can receive an automated instruction to depart early to compensate for the additional driving time and thus prevent production stoppage. At the same time, a foreman will receive a warning so that he can set further counteractions in motion if necessary.

TECHNICAL IMPLEMENTATION

The tugger trains are equipped with infsoft Locator Tags with UWB module which measure the distance (Time of Flight, ToF) to the infsoft Locator Nodes which are installed throughout the entire area. The Locator Nodes send the information to the infsoft LocAware platform®, where the position is determined with an accuracy of 10-30 centimeters and very low latency. Using a mobile app or a browser application, the position data can be accessed and seen on a digital map.

By recognizing patterns and regularities in existing data, infsoft Machine Learning is able to make precise forecasts of the probability of delayed tugger trains and production stoppages. The predictions are then provided to infsoft Analytics and the Automation Engine. It is previously defined in the Automation Engine, which action should be performed at which probability. For example, automated messages containing instructions or warnings can be sent to the driver or the tugger train management.

Additional data sets, for example tugger train availability and inventory levels of certain components, can further enhance the machine learning forecasts.