By implementing a localization system in logistics, goods in large warehouses can be found fast and reliably.

AT A GLANCE

- 3D server-based localization of goods

- location overview in digital 2D/3D map

PROBLEM DEFINITION

In warehouses there are several thousand goods that are stored and transported to further processing by industrial trucks. Required goods are not always located at the expected or best possible location. In many cases employees have to search for them first which results in process delays and high costs.

SOLUTION

By implementing a tracking solution, the location of required goods can be determined reliably. Goods can be located with high accuracy so that it is possible to identify the exact shelf on a high rack on which the searched item can be found. The goods’ locations can be viewed on a digital map at any time. This results in reduced search times, ideal warehousing and efficient process management.

TECHNICAL IMPLEMENTATION

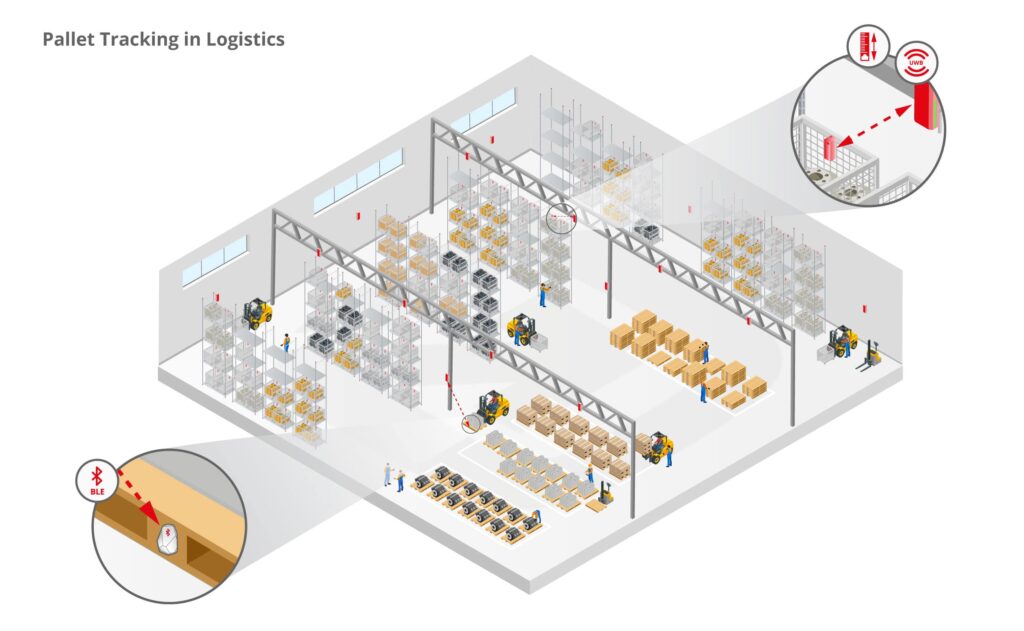

Depending on the goods and the method of storage, different localization technologies can be implemented.

Bluetooth Low Energy beacons are attached to euro pallets on which comparably low priority goods are stored.

High priority goods are stored in pallet cages on high racks. The pallet cages are equipped with infsoft Locator Tags with UWB module. The benefits of locating objects with ultra-wideband are the high accuracy of 10-30 centimeters and the possibility of 3D localization. The positioning of the pallet cages is realized using a transit time method (Time of Flight, ToF). The Locator Tag measures the running time of light between itself and at least three infsoft Locator Nodes. By including a fourth Locator Node at the ceiling of the warehouse, in addition to the x- and y-coordinate, the z-coordinate of the searched object and therefore the shelf height can be determined.

Infsoft Locator Nodes, which are installed throughout the entire area, receive the data from the BLE beacons and UWB tags and send them to the infsoft LocAware platform® where they are processed. Using a mobile app or a browser application, employees can access the position data and see the location of the goods on a digital map.